WHAT IS THE DIFFERENCE BETWEEN FE500 AND FE500D TMT BARS?

Electrotherm Steel | September 5, 2019

Electrotherm Steel | September 5, 2019

SUPERIOR QUALITY TMT BAR

TMT bars are backbone of every civil construction deep rooted into foundation they bear the load of building, slabs, beams, columns and of course the live load of the people and their belongings. And as the strength of every structure,the TMT bars have to be ready to withstand the loads including windstorms and earthquake.Poor quality materials such as cheap steel bars usually contain high levels of unknown elements which are harmful for construction. This means that the steel bars do not have required chemical and physical properties. Now customer is alert and due to higher level education and better purchasing power, They need better quality of product and prepare to pay for it. TMT steel bars are steel bars that are manufactured with unique metallurgical process known as “Thermo Mechanical Treatment”. These TMT bars are approved by the Bureau of Indian Standards for building and construction projects. The Fe 500 and Fe 500D are some of the best TMT Bars in India.

CHEMICAL STRUCTURE OF TMT BARS

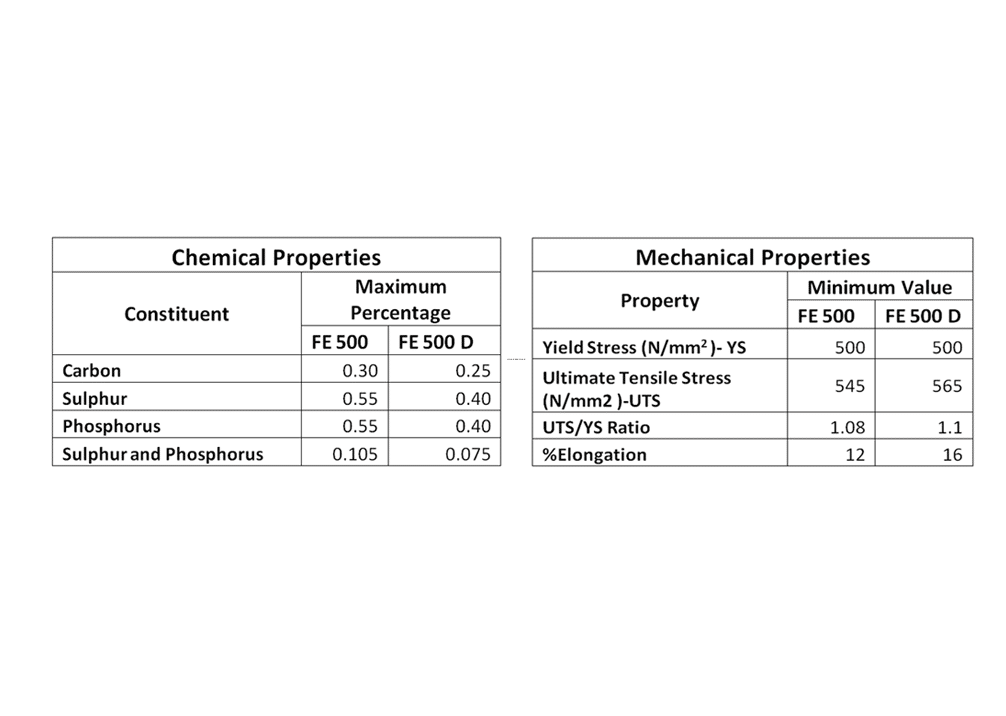

In the Fe 500 & Fe 500D the term “Fe” denotes Iron,”500” stands for the minimum yield stress in N/mm2 and the letter “D” denotes that such bars have higher values of ductility (higher UTS/YS & % Elongation). These bars have lower percentages of sulphur and phosphorus which are harmful for steels used in construction. Higher sulphur leads to “Hot Shortness” wherein the melting point of steel is lowered, leading to failure under extreme high temperature conditions. Higher phosphorus leads to “Cold Shortness” wherein the steel becomes brittle under extremely cold conditions and leads to cracking. Also, the value of Carbon percentage in these bars is low to improve the ductility and weldability of steel.

These FE 500 D and FE 500 steel specification bars are crafted under strictly regulated manufacturing process which makes them easily bendable. There is an important connection between concrete and steel. Concrete has great compressive power but relatively low tensile strength and ductility, therefore when it fuses with TMT steel bars; it gives rise to a highly ductile and tensile combination.

While both Fe500 and Fe500D TMT bars are the best TMT bars for construction projects, the Fe500D TMT bars certainly comes with a greater ductile strength than the Fe500 TMT bars. The Tensile strength of steel remains the same for both these products. However, it is the overall ductility that makes all the difference. Ductility is the ability of the material, to plastically deform and adapt while being stressed with a tensile load.When a piece of ductile material is pulled, before rupture (breaking apart), is will deform, change its shape to adapt to the stress. By doing so it will also absorb energy, represented by the area under the curve AB’ in the picture below.

The opposite of ductility is brittleness. A brittle material absorbs, during stress, very little energy (the area under the curve AB) and is, usually, not even plastic (in the example below it has a very limited plasticity).

This feature provides the Fe500D TMT bars with the capacity to absorb sudden loads, which make them ideal for various natural disasters like earthquakes, tsunamis and cyclones. The high safety features offered by Fe500D TMT bars make them well suited for zones having high seismic activity.

To meet the stringent phosphorous and sulphur requirement of Fe500D grade of TMT bars , after melting the sponge Iron and hot metal from blast furnace, a unique and patented ERF-ELdFOSTM metallurgical process is used to dephosphorize the steel in the ladle and desulphurize the steel in Electrotherm Ladle Refining Furnace and now steel thus produced at ET is at par with Primary steel producers.

Multi stage testing of steel chemistry is done through spectrometer to ensure adherence to chemistry in close tolerance. Stringent quality control is done through in house NABL approved laboratory.

In the Ladle Refining furnace metal is homogenized, alloying elements are added to control chemistry in narrow range, dissolved gases are reduced and inclusions are removed to ensure improved quality.

This refined steel is cast into billets in controlled conditions to minimize gaseous and slag inclusions.

Also minimizing use of scrap brings control over tramp elements like Cu,V,Ni,Cr etc.

These billets are rolled in rolling mill with world renowned Thermax accredited water quenching box to achieve desired physical properties.

The chemical and mechanical properties are given below:

Yield Stress –Stress (load per unit cross sectional area) at which a material begins to deform plastically. Prior to the yield point, the material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible.

Ultimate Tensile Stress– The amount of tensile (stretching) stress a material can withstand before failing or breaking.

Categories: Blog Tags: Difference Between Fe500 & Fe500D, Fe500 vs Fe5000D