Frequently Asked

Questions

General Information

Technical Specifications

Manufacturing and Process

Usage and Applications

Standards and Certifications

Corrosion Resistance

Earthquake Resistance

Cost and Purchase

Handling and Storage

Environmental Impact

Miscellaneous

General Information

1. What are TMT bars?

TMT (Thermo-Mechanically Treated) bars are high-strength reinforcement bars with a tough outer core and a soft inner core. They are widely used in construction for their superior strength and flexibility.

2. What are the grades of TMT bars available?

Common grades include Fe-500, Fe-550, and Fe-600. The numbers represent the yield strength of the bars. We also offer grades such as

Fe 500D and Fe 550D, each suitable for different construction needs.

3. Why are TMT bars preferred in construction?

TMT bars offer high strength, better ductility, superior bendability, corrosion resistance, earthquake resistance, and weldability, making them ideal for construction.

Next: Technical Specifications

Technical Specifications

1. What is the yield strength of TMT bars?

Yield strength varies by grade: Fe-500 has 500 MPa, Fe-550 has 550 MPa and Fe-600 has 600 MPa.

2. What is the elongation property of TMT bars?

Elongation indicates ductility. Higher grades like Fe-500 and above generally have lower elongation percentages than Fe-415.

3. What are the standard sizes available for TMT bars?

TMT bars are available in diameters ranging from 8mm to 40mm.

4. How are TMT bars tested for quality?

TMT bars undergo various tests, including tensile tests, bend tests, re-bend tests, and chemical composition analysis.

Manufacturing and Process

1. How are TMT bars manufactured?

TMT bars are manufactured through a process involving rapid quenching, self-tempering, and atmospheric cooling to create a high-strength outer layer and a ductile core.

2. What is the quenching process in TMT bar manufacturing?

Quenching involves rapid cooling of the hot steel bars using water jets, which creates a tough outer layer while the core remains hot and ductile.

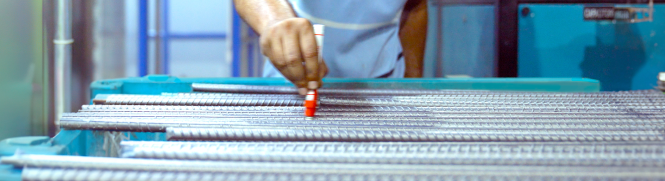

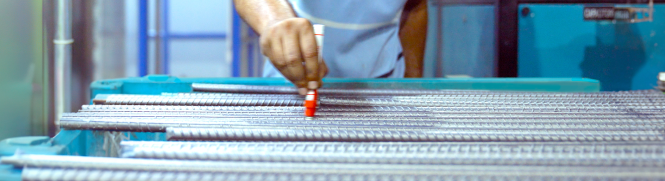

3. What is the significance of the rib pattern on TMT bars?

The rib pattern enhances the bonding strength between the bar and concrete, preventing slippage in reinforced concrete structures.

Next: Usage and Applications

Usage and Applications

1. Where are TMT bars commonly used?

TMT bars are used in various construction projects, including residential buildings, commercial complexes, bridges, dams, and industrial structures.

2. Can TMT bars be welded?

Yes, TMT bars can be welded. However, proper welding techniques and preheating are necessary to maintain the bar’s properties.

3. What is the difference between primary and secondary TMT bars?

Primary TMT bars are manufactured by large, integrated steel plants using virgin iron ore, while secondary TMT bars are produced by smaller plants using recycled steel scrap.

4. Can TMT bars be used in seismic zones?

Yes, TMT bars are designed to withstand high stress and are suitable for use in earthquake-prone areas due to their superior ductility and strength.

Standards and Certifications

1. What are the standards for TMT bars in India?

The Bureau of Indian Standards (BIS) specifies standards for TMT bars, such as IS 1786:2008.

2. Are your TMT bars certified?

Yes, our TMT bars meet international standards and are certified by ISO, BIS, and other relevant authorities.

3. How to identify genuine TMT bars?

Genuine TMT bars have clear branding, consistent rib patterns, proper dimensions, and certifications from reputed standards organizations like BIS.

Next: Corrosion Resistance

Corrosion Resistance

1. Are TMT bars resistant to corrosion?

Yes, TMT bars have enhanced corrosion resistance due to their manufacturing process, which includes quenching and self-tempering.

2. How to improve the corrosion resistance of TMT bars?

Using epoxy coating, galvanized TMT bars, or adding corrosion inhibitors to the concrete mix can improve corrosion resistance.

Next: Earthquake Resistance

Earthquake Resistance

1. Why are TMT bars considered earthquake resistant?

TMT bars have high ductility and strength, allowing them to absorb and dissipate energy during seismic events, reducing structural damage.

Next: Cost and Purchase

Cost and Purchase

1. Where can I buy TMT bars?

TMT bars can be purchased from authorized dealers, construction material suppliers, and directly from manufacturers.

2. What should I consider when purchasing TMT bars?

Consider the grade, size, certification, brand reputation, and price. Ensure the bars meet the required standards for your project.

3. How can I place an order for TMT bars?

You can place an order through our website or by contacting our sales team via phone or email.

4. What is the delivery time for TMT bars?

Delivery times vary based on order quantity and location, but typically, orders are fulfilled within 7-10 business days.

Next: Handling and Storage

Handling and Storage

1. How should TMT bars be stored?

Store TMT bars in a dry, covered area to prevent rusting. They should be stacked in a way that allows air circulation and easy access.

2. How to handle TMT bars on construction sites?

Use proper lifting equipment and techniques to prevent bending and physical damage to the bars.

Next: Environmental Impact

Environmental Impact

1. Are TMT bars environmentally friendly?

Yes, TMT bars are made from recycled steel, and their long lifespan reduces the need for frequent replacements, thereby minimizing environmental impact.

2. What are the sustainability aspects of using TMT bars?

TMT bars contribute to sustainable construction by providing long-lasting durability, reducing the need for frequent repairs and replacements.

Next:Miscellaneous

Miscellaneous

1. Can TMT bars be recycled?

Yes, TMT bars can be recycled, contributing to the circular economy and reducing waste.

2. How do TMT bars contribute to the longevity of structures?

Their high strength, ductility, and resistance to corrosion and seismic forces enhance the durability and lifespan of structures.

3. What is the difference between cold-twisted and hot-rolled TMT bars?

Cold-twisted bars undergo a mechanical twisting process, while hot-rolled TMT bars are produced using a thermomechanical treatment for superior properties.

4. Are TMT bars suitable for all types of construction?

Yes, TMT bars are versatile and suitable for a wide range of construction projects, from residential to large-scale infrastructure.

1. What are TMT bars?

TMT (Thermo-Mechanically Treated) bars are high-strength reinforcement bars with a tough outer core and a soft inner core. They are widely used in construction for their superior strength and flexibility.

2. What are the grades of TMT bars available?

Common grades include Fe-500, Fe-550, and Fe-600. The numbers represent the yield strength of the bars. We also offer grades such as

Fe 500D and Fe 550D, each suitable for different construction needs.

3. Why are TMT bars preferred in construction?

TMT bars offer high strength, better ductility, superior bendability, corrosion resistance, earthquake resistance, and weldability, making them ideal for construction.

Next: Technical Specifications

1. What is the yield strength of TMT bars?

Yield strength varies by grade: Fe-500 has 500 MPa, Fe-550 has 550 MPa and Fe-600 has 600 MPa.

2. What is the elongation property of TMT bars?

Elongation indicates ductility. Higher grades like Fe-500 and above generally have lower elongation percentages than Fe-415.

3. What are the standard sizes available for TMT bars?

TMT bars are available in diameters ranging from 8mm to 40mm.

4. How are TMT bars tested for quality?

TMT bars undergo various tests, including tensile tests, bend tests, re-bend tests, and chemical composition analysis.

1. How are TMT bars manufactured?

TMT bars are manufactured through a process involving rapid quenching, self-tempering, and atmospheric cooling to create a high-strength outer layer and a ductile core.

2. What is the quenching process in TMT bar manufacturing?

Quenching involves rapid cooling of the hot steel bars using water jets, which creates a tough outer layer while the core remains hot and ductile.

3. What is the significance of the rib pattern on TMT bars?

The rib pattern enhances the bonding strength between the bar and concrete, preventing slippage in reinforced concrete structures.

Next: Usage and Applications

1. Where are TMT bars commonly used?

TMT bars are used in various construction projects, including residential buildings, commercial complexes, bridges, dams, and industrial structures.

2. Can TMT bars be welded?

Yes, TMT bars can be welded. However, proper welding techniques and preheating are necessary to maintain the bar’s properties.

3. What is the difference between primary and secondary TMT bars?

Primary TMT bars are manufactured by large, integrated steel plants using virgin iron ore, while secondary TMT bars are produced by smaller plants using recycled steel scrap.

4. Can TMT bars be used in seismic zones?

Yes, TMT bars are designed to withstand high stress and are suitable for use in earthquake-prone areas due to their superior ductility and strength.

1. What are the standards for TMT bars in India?

The Bureau of Indian Standards (BIS) specifies standards for TMT bars, such as IS 1786:2008.

2. Are your TMT bars certified?

Yes, our TMT bars meet international standards and are certified by ISO, BIS, and other relevant authorities.

3. How to identify genuine TMT bars?

Genuine TMT bars have clear branding, consistent rib patterns, proper dimensions, and certifications from reputed standards organizations like BIS.

Next: Corrosion Resistance

1. Are TMT bars resistant to corrosion?

Yes, TMT bars have enhanced corrosion resistance due to their manufacturing process, which includes quenching and self-tempering.

2. How to improve the corrosion resistance of TMT bars?

Using epoxy coating, galvanized TMT bars, or adding corrosion inhibitors to the concrete mix can improve corrosion resistance.

Next: Earthquake Resistance

1. Where can I buy TMT bars?

TMT bars can be purchased from authorized dealers, construction material suppliers, and directly from manufacturers.

2. What should I consider when purchasing TMT bars?

Consider the grade, size, certification, brand reputation, and price. Ensure the bars meet the required standards for your project.

3. How can I place an order for TMT bars?

You can place an order through our website or by contacting our sales team via phone or email.

4. What is the delivery time for TMT bars?

Delivery times vary based on order quantity and location, but typically, orders are fulfilled within 7-10 business days.

Next: Handling and Storage

1. Where can I buy TMT bars?

TMT bars can be purchased from authorized dealers, construction material suppliers, and directly from manufacturers.

2. What should I consider when purchasing TMT bars?

Consider the grade, size, certification, brand reputation, and price. Ensure the bars meet the required standards for your project.

3. How can I place an order for TMT bars?

You can place an order through our website or by contacting our sales team via phone or email.

4. What is the delivery time for TMT bars?

Delivery times vary based on order quantity and location, but typically, orders are fulfilled within 7-10 business days.

Next: Handling and Storage

1. How should TMT bars be stored?

Store TMT bars in a dry, covered area to prevent rusting. They should be stacked in a way that allows air circulation and easy access.

2. How to handle TMT bars on construction sites?

Use proper lifting equipment and techniques to prevent bending and physical damage to the bars.

Next: Environmental Impact

1. Are TMT bars environmentally friendly?

Yes, TMT bars are made from recycled steel, and their long lifespan reduces the need for frequent replacements, thereby minimizing environmental impact.

2. What are the sustainability aspects of using TMT bars?

TMT bars contribute to sustainable construction by providing long-lasting durability, reducing the need for frequent repairs and replacements.

Next:Miscellaneous

1. Can TMT bars be recycled?

Yes, TMT bars can be recycled, contributing to the circular economy and reducing waste.

2. How do TMT bars contribute to the longevity of structures?

Their high strength, ductility, and resistance to corrosion and seismic forces enhance the durability and lifespan of structures.

3. What is the difference between cold-twisted and hot-rolled TMT bars?

Cold-twisted bars undergo a mechanical twisting process, while hot-rolled TMT bars are produced using a thermomechanical treatment for superior properties.

4. Are TMT bars suitable for all types of construction?

Yes, TMT bars are versatile and suitable for a wide range of construction projects, from residential to large-scale infrastructure.

Submit Your Queries

Last updated on 10th July, 24

Latest News

10th July, 2024

Exploring the Advantages of

Epoxy Coated TMT Bars

Exploring the Advantages of Epoxy Coated TMT Bars

10th July, 2024

Exploring the Advantages of

Epoxy Coated TMT Bars

Exploring the Advantages of Epoxy Coated TMT Bars

Have Questions? Call us Now

Sales: +91 8238079223

Need Support? Write to us

salestmt@electrotherm.com