- Home

- >

- FAQ

FAQ

What are MS Round bars?

Plain hot rolled round bars are called MS Round bars.

What are the characteristics of MS Round bars?

- Low yield strength (Fe-250)

- Low bond strength

- High elongation

- High UTS / YS ratio

No technology is currently available to increase the strength and roll a uniform ribbed bar.

What are Cold Twisted rebars?

Hot rolled bars with cold twisting after rolling are called cold twisted rebars.

What are the characteristics of cold twisted rebars?

- High yield strength

- Higher bond strength

- Low elongation

- Poor corrosion resistance

The technology was not available to improve the strength without sacrificing other properties.

What are Thermo Mechanically Treated bars?

Hot rolled ribbed bars with online quenching/tempering are called Thermo Mechanically Treated bars.

What are the characteristics of thermos mechanically treated bars?

- High yield strength

- High bond strength

- High elongation

- Higher UTS / YS ratio

- Higher corrosion resistance

TMT bars are highly superior compared to others in all critical quality parameters.

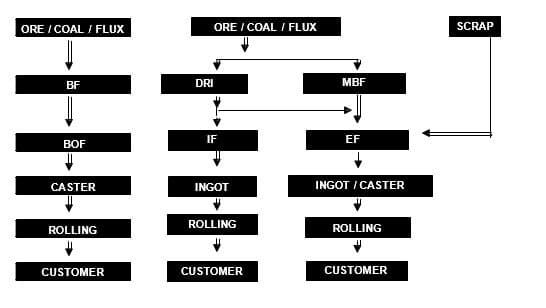

Manufacturing routes of rebars

Rebars can be manufactured by the following processes:

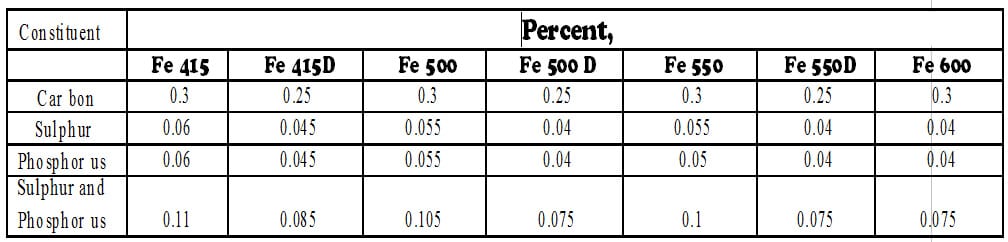

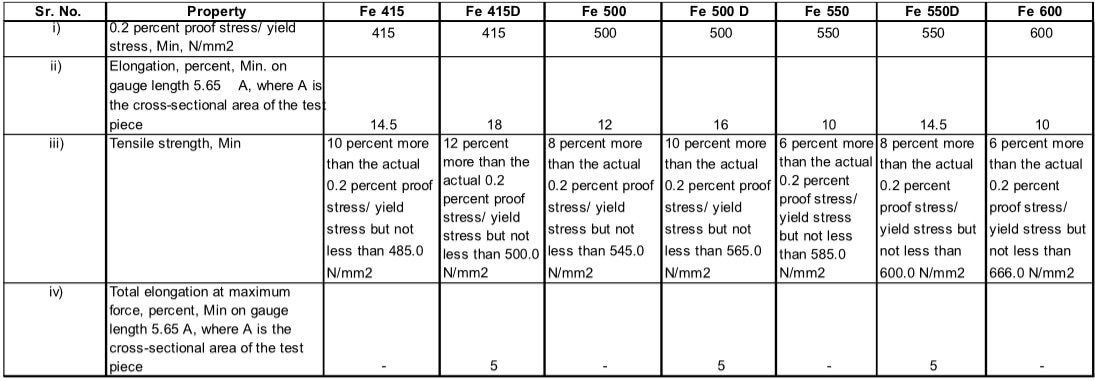

Mechanical and Chemical Properties (BIS 1786:2008)

What is the usage of Rebars in RCC Structure?

Any building during its existence encounters three types of loads:

i. Dead Load:

This is the static load of the building itself including the weights of roof, beams, walls, water tank, etc. which are fixed.

ii. Live Load:

This is the additional loads over the dead load like furniture, other appliances, people, stored water, plantations, etc. and varies in

nature.

iii. Lateral Load:

These are the loads created by winds, ground vibration, rains,earthquake, etc. and are mostly unpredictable.

Major constituents of RCC buildings:

- Sand, coarse aggregate, binder (cement/lime, etc.) to make concrete

- Masonry like bricks

- Cementing materials: sand, binder (cement/lime, etc.)

- Reinforcement bars

The above constituents are used to construct Structural and Non-Structural members of a building.

Structural Members are constructed to withstand the major structural loads/stress of a building and common structural members are:

- Columns

- Beams or slabs

- Lintel

- Roof

Nonstructural members are not supposed to withstand major loads

- Façade

- Masonry (in case of non-load bearing walls)

- Doors/windows etc.

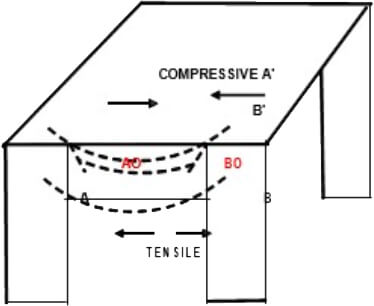

A Structural Member in a building encounters two basic types of loads:

- Compressive

- Tensile

E.g: In a column, there is compressive stress mostly as the weight of the building

tries to compress the column. In a beam, there is both compressive and tensile load as under:

Who can bear both Tensile and Compressive Loads?

- Concrete (without reinforcement) has a very high compressive strength and can bear such loads excellently.

- But concrete practically has a very poor tensile strength and bendability – just breaks under heavy tensile load.

- If a building is constructed with only concrete, the beams at the lower portion are likely to develop a crack and break when the tensile stress developed at that

Portion.

Therefore, to make the building enable to withstand both tensile and compressive stress, steel reinforcement is used.

Is there a difference in the quality of TMT bars made by ET TMT and Tata Tiscon /RINL /SAIL made TMT?

Tata Steel, SAIL, RINL and JSW and Electrotherm, all produce steel through the iron ore route. This ensures that the steel produced is free from tramp elements. While Tata, SAIL, RINL, and JSW use BF-BOF-LRF route for the production of steel, Electrotherm uses BF-Sponge Iron-IF-LRF route for the production of the same. The use of LRF (ERF+ELdFOS™) ensures refining of steel, desulphurization,dephosphorization, homogenization, inclusion flotation and low gas levels which results into highest quality of steel confirming to most stringent BIS norms.

What is the Rebar requirement for the construction of a house?

The consumption of rebars for construction of any house depends on various factors, like the design of the house, the depth of foundation, no. of stories, etc. However, in a two-storied building, the consumption of rebar per sq. ft. is approximately 4-4.5 kg as per the thumb rule.

What is TMT?

TMT stands for Thermo-Mechanical Treatment. A process that is far superior to the conventional manufacturing process.

What is ET TMT?

ET TMT is a superior rebar manufactured through the TMT Process by Electrotherm India Ltd.

What is the size range for ET TMT?

ET TMT is available from 8 mm to 40 mm.

Where can I get ET TMT?

ET TMT has a wide distribution network. Please call us on 02717-660550/649 to get the details of the nearest distributor in your area.

As per BIS, what grade is ET TMT?

ET TMT falls within the specifications of BIS 1786:2008. We offer Fe 500, Fe 500 D,Fe 550, & Fe 550 D. We also offer CRS grades in all these varieties.

What is the difference between ET TMT and any other rebar in the market?

ET TMT is the rebar in the market today that provides consistent mechanical and chemical properties, rebar after rebar. Strong quality control, ensures that each rebar reflects the trust and quality that ET TMT name commands.

How will it be delivered to me?

ET TMT comes in easy to handle transport bundles, of standardized weight and a fixed number of bars per bundle.

Can we use Reddish / Rusty Rebar for constructions, which were lying outside during rainy season?

Rebars develop reddish colour at times due to coming into direct contact with moisture and air. However, reddish rebars can very well be used in construction, if they are in proper physical form, weight, and strength.

Is any Anti-Corrosion steel available?

Yes, there are certain alloying elements which when added to steel, induce anti-corrosion properties. The most common example is stainless steel where elements like Cu, Ni & Cr are used to a substantial quantity to make it anti-corrosion. In some very expensive constructions, Stainless Steel Rebars have also been used abroad. However, for general construction stainless steel variety cannot be used as rebar reinforcement, because the cost of such rebars will be nearly five times more than the conventional rebars.

However, for coastal areas & water tanks, CRS grades made by ET TMT are recommended.

ET TMT also offers Epoxy Coated Rebars and it is mainly used in making bridges and roads. It is also recommended by the government for government projects in their tender documents. In the case of specific enquiries, ET TMT can also offer the same to other customers as well.